Nearly a year ago, I wrote a guest post about bronze swords:

• how the metals were extracted from the earth

• how the weapons were smithed

• and why they were more effective than the early efforts from the Iron Age.

The blog on which my post appeared is an active one, hosted by a talented and prolific sister author. She generates fresh material for her site every day, and my post has long been buried under 365 days of impressive creativity!

Given my latest streak of posts about steel swords, now seems a grand time to revive my research on bronze swords and present it on my own blog. 😀

Tracking down knowledge is my drug of choice. Each new fact is just so interesting! Even better is the moment when an entire constellation of facts coalesces, and I see how it all fits together and what it all means. That’s a total thrill!

But my insatiable curiosity (and I seem to be able to be curious about everything and anything) was not why I researched bronze metallurgy in ancient times. I was writing a novel set in the Bronze Age of my North-lands, and my protagonist was essentially the treasurer for a warlord. The wealth of the citadel lay in its metals and – especially – its weapons. So I needed to know all about how the metals were extracted from the earth, how they were purified and poured into ingots, and what forging techniques were used. My protag knew all that stuff, so I needed to know about it also.

For those of you who share my curious bent, here’s what I discovered.

Too many of the sources I found were overly theoretical. The author might explain why ancient cultures developed metallurgy as they did or how they traded for their tin. But I needed nitty gritty details.

How were their smelting furnaces set up? How long did it take for the metal to become molten? How exactly did the ancients fashion bronze scale mail? How did they make their bronze swords?

Historical re-enactors and experimental archeologists proved to be my most fruitful sources. I found actual patterns for re-creating bronze helmets and bronze armor, along with photos of the finished results. I found videos showing Bronze Age combat techniques.

The website of Neil Burridge, a smith who creates Bronze Age artifacts using authentic materials and methods, had the details I was truly seeking. Videos of him in action allowed me to see a real smith moving within the forging environment, garbed in the protective gear of heavy apron and gauntlets, using the tongs and crucibles, exercising prudence with the liquid fire that is molten metal.

He also explained vividly the awe with which the ancient smiths were probably regarded. Metallurgy was not a theoretical science for them. It was a practical discipline, absolutely necessary for their tools and weapons, but with techniques developed over hundreds of years and handed down from one smith to another.

They didn’t know why these techniques worked. And they weren’t infallible. Sometimes a pour would turn out a perfect result. Other times it would fail, and the smith wouldn’t know for sure what had caused the failure. Certainly ordinary people, with no access to a smith’s secrets, would have regarded the whole business as magical.

Although the people in my novel were using Bronze Age technologies, I envisioned them as possessing military organization more like the armies of ancient Rome. Thus my smiths would not spend days setting up for the pouring of one sword that might – or might not – deliver success. They would pour many blades in one day, and then hand the blades off to others for the steps that transformed the plain metal blank into a weapon.

Anvilfire.com, a website “dedicated to advancing modern blacksmithing while retaining traditional standards of craftsmanship,” supplied me with information about this finishing process. The bladesmith created the blade. A separate shop did the grinding and polishing. Yet a third made the hilt and secured the blade to it. And a fourth made the scabbard.

Making a sword was resource intensive, both because of the valuable metals required and because of the labor from many skilled individuals that went into it.

So what about those materials? Bronze is made by mixing a small part of tin with a larger portion of copper. The ancients didn’t have modern strip mines or deep underground mines. Nor did they have sophisticated machinery run by diesel engines. How did they get copper and tin out of the ground?

Copper mines bore some resemblance to my expectations. The copper deposits needed to be relatively near the surface, but the ancients actually did tunnel down to a vein of ore. There, at the working face, they built a fire to heat the ore-containing rock. Once the rock reached a high enough temperature, they doused it with cold water. This process increased the brittleness of the rock and induced a preliminary degree of cracking. Blows from a hammer or pick could then break it into rubble, which could be heated in a smelting furnace to extract the copper.

Tin was another matter, one entirely new to me.

Tin was found in alluvial deposits in stream beds, usually as a very pure tin gravel well stirred with gravels of quartz, mica, and feldspar (gangue). So the trick was to separate out the tin gravel from the others.

The method of the ancients, as far back as 2,000 BC, was this:

• Dig a trench at the lowest end of the deposit.

• Dig a channel from the nearest water source to pour water over that part of the deposit

• Allow the stream of water to wash the lighter gangue into the trench

• Pick up the heavier tin gravel that remained

• When the lower portion of the deposit had yielded all its tin, dig another trench a bit higher and redirect the water channel, to allow the next section of the deposit to be harvested

The tin gravel thus obtained would be roughly smelted on site, simply roasting the gravel in a fire. The pebbles resulting from this rough smelt would then be transported to a dedicated furnace for a second smelting that yielded the purer tin needed by bladesmiths.

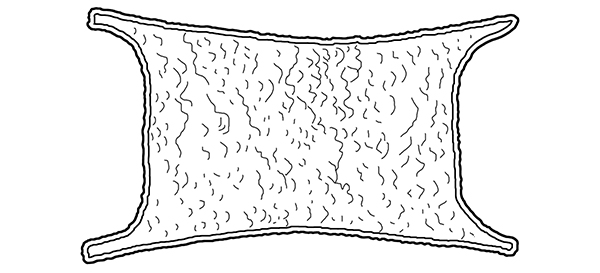

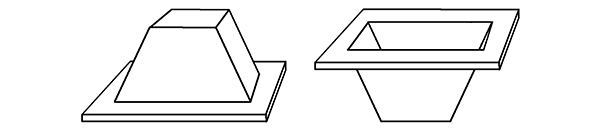

Modern ingots are rectangular blocks, but those of the ancients took several different forms. The earliest were so-called “biscuit” ingots, round on the bottom like a muffin, gently concave on the top. They took the shape of the earthen pit into which the molten metal dripped from the smelting furnace.

But metal is heavy, and the biscuit shape awkward to carry. Around our own Mediterranean, an “oxhide” form was developed. It weighed about 80 pounds and possessed four “legs,” one at each corner, that allowed it to be tied between pack animals or gripped and carried by men.

I became fascinated with an ingot form used much later by the Chinese in the Malay Penninsula. These were hat shaped, much smaller (weighing only a pound), and actually used as currency.

Bronze has one very peculiar property in the smithy.

Most metals, such as iron or even copper, when heated and cooled slowly to room temperature, become more ductile and more workable. They are less prone to internal stresses.

Bronze does not behave like this. When slow cooled, it becomes brittle and difficult to work. Thus it must be heated to cherry-red and then quenched in water. This quick cooling makes it so soft that it can then be hammered. The hammering condenses the metal, giving it more rigidity.

A bladesmith will hammer near the edge of a blade to harden it and help it keep its sharpness, while allowing the center rib to retain more of its resilience.

If you compare a bronze sword to a steel sword, the steel is always going to win. But when the Bronze Age gave way to the Iron Age, bronze metallurgy was at its peak. Several thousand years had gone into the development of the most superb techniques. Iron metallurgy was in its infancy, and getting the iron swords to be rigid enough was a problem. The iron swords just weren’t as good as the bronze ones, which were light, strong, just rigid enough, and held an edge well.

But there’s no need to take my word on this. A YouTuber with a passion for swords, Skallagrim from Canada, discourses quite knowledgeably about the pros and cons of bronze. More amusingly, he tests one of Neil Burridge’s bronze swords “to destruction” in the video below.

(There’s a brief reprise snippet of Mr. Burridge before Skallagrim gets going with his destruction. Go to the 3:30 mark, if you want to skip that snippet.)

Even after all my research, I cannot call myself more than a mere smatterer. I learned enough to write The Tally Master, and not much more. But I hope you found these tidbits entertaining, and I’ll be happy to answer questions in the comments below. Or to speculate with you, when I don’t know the answer. 😉

For more about The Tally Master, see:

Gael’s Tally Chamber in Belzetarn

Mapping Ancient Rome onto Belzetarn

What Does the Tally Master Tally?

Map of the North-lands in the Bronze Age

The Fortress of Belzetarn

The Dark Tower

Belzetarn’s Smithies and Cellars

Belzetarn’s Formidable Entrance Gate

Belzetarn’s Treasures

Belzetarn’s Great Halls

Brother Kings